The only official English website: www.hq-carbon.com,Our company has not authorized other companies or individuals to act on our behalf.

Please take precautions to avoid being deceived.

We often use graphite crucible in our life. Let's talk about the precautions for crucible uses.

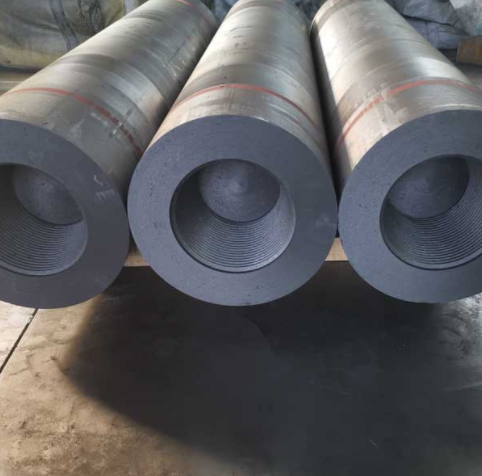

The main material of the graphite crucible is crystalline natural graphite. Therefore, it maintains the original physical and chemical properties of natural graphite.

Graphite crucible has good thermal conductivity and high temperature resistance, in the process of high temperature use, thermal expansion coefficient is small, the rapid heat, rapid cooling has a certain resistance to strain. The corrosion resistance to acid and alkaline solution is strong, and it has excellent chemical stability.

Graphite crucible, because of the above excellent performance, so in metallurgy, casting, machinery, chemical and other industrial sectors, is widely used in the smelting of alloy tool steel and non-ferrous metal and its alloy smelting. And has a better technical and economic effect.

Special handling tools must be used to carry the crucible, and it is not allowed to roll the crucible directly on the ground. During handling, collision should be avoided to avoid damage to the glaze layer, thus affecting the service life of the crucible.

Cauldrons must be kept in a dry, ventilated place, preferably on wooden brackets. Do not put the crucible directly on the brick, earth or cement floor, the crucible will be affected by moisture will lead to damage to the glaze layer, which will reduce the melting efficiency and service life of the crucible, and even the bottom will fall off in serious cases.

1.1 check whether the inner wall and bottom of the crucible furnace are intact.

1.2 check whether there is residual slag in the furnace, if so, remove it in time.

2.1 the crucible base shall be of the same shape as the bottom of the crucible and slightly larger in size (about 2cm).

2.2 for different types of crucible furnaces, appropriate height of crucible base should be selected.

2.3 avoid using waste crucible base, otherwise the crucible life will be greatly shortened.

3.1 installation of gas or oil crucible: first place the crucible on the base, and reserve a certain expansion space for the crucible between the crucible and the top of the furnace wall, and use wood blocks, cardboard and other materials to fix it. Adjust the position of the burner and nozzle so that the flame is aligned with the combustion chamber, not directly at the bottom of the crucible.

3.2 installation of crucible for rotary furnace: the crucible shall be fixed on both sides of the pouring nozzle of the crucible with supporting bricks, and the crucible shall not be wedged tightly. Meanwhile, between the supporting brick and the crucible, materials such as paperboard and so on about 3-4mm are inserted to serve as the pre-expansion space of the crucible.

3.3 installation of crucible for electric furnace: the crucible shall be placed in the center of the resistance furnace and the bottom of the crucible shall be higher than the bottom row of heating elements. At the same time between the top of the crucible and the furnace edge of the use of insulation cotton seal.

3.4 installation of crucible for induction furnace: ensure that the crucible is placed in the center of the induction coil to avoid local overheating and cracking of the crucible.

The service life of a crucible can be greatly extended by preheating it in the right way.

4.1 according to different types of crucible furnaces, when the crucible is used for the first time, preheat the crucible to about 200℃ in 30 minutes without adding materials, and dry it for 60 minutes. Objective to make the surface of crucible absorb water and evaporate. Prevent the use of the initial burst.

4.2 after preheating, the crucible should be heated to 900℃-1000℃ (about 2 hours) as soon as possible, and keep warm for 20-30 minutes, then rise to or drop to the working temperature. The purpose is to quickly pass through the graphite crucible readily oxidized temperature region.

4.3 it is usually not necessary to reheat a crucible after the first preheating, unless the crucible is damp again. Reheat the crucible after each stop.

So that's the thing to note before you start using the graphite crucible, so keep watching us for more graphite crucible questions.We also have HP Graphite Electrode.Please contect us.

Copyright © Linzhang County Hengqiang Carbon Co.,Ltd All Rights Reserved Sitemap |